Paul Cangialosi and the JT5 Equipped Low Drag Coupe

Paul Cangialosi and the

JT5 Equipped Low

Drag Coupe

Its been over a year since I dropped off a 5 speed in the UK custom built for the Low Drag Coupe project. After spending a week in Germany with Tony Parkinson of Vicarage Motor Cars ( USA ) working a trade show, we headed off to England to see the shop that was going to do the work on assembling the car. I think at the time the only actual pieces of the car I may have seen were the seats and my 5 speed transmission. I remember drinking massive amounts of tea and working in a poorly lit shop with damp floors.

Almost year later ( March,2000 ) Tony flys out to England to do a test drive of the car. His mission is to get most of the kinks worked out before BBC's Top Gear Magazine films a segment for their TV show and writes an article for the April issue. You have to give Tony a great deal of credit to be able to coordinate a large group of people to complete a project like this.

|

|

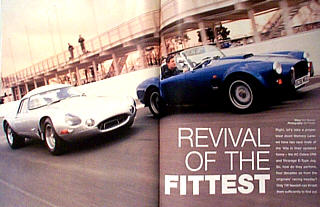

The review in Top Gear to me was just OK. It was great to have Tiff Needell

drive the car and get his input. Some stuff said was " The Jag's carburation

( three twin-choke Webers with K & N filters ) feels a bit fluffy at low

revs and there's a healthy helping of period mechanical clatter" or "press

the E's amusingly long travel throttle, wait briefly for the revs to reach about

2000"...and so forth. One thing they overlooked is that the car is suppose

to be a blend of period piece racer and still be street legal. The concept is

to have that vintage feel, still have air conditioning, yet be able to stab

the throttle and crank out some serious power. It was time for Tony to ship

the car to the states so that we can fix all the bugs and get the car set up

for what our intended concept was.

|

Sometime in late May the Low Drag arrives at the Jaguar Doctor facility located next door to my gear shop. Being that the shop is in such close proximity it gives me the opportunity to take time out from my already busy schedule and work with Thierry, Luc and Jake ironing out bugs. This car was assembled in England just a few months prior to its arrival. Upon examination of the car, although it was new, it had already all the typical English characteristics Americans joke about. Great coach and body work, great interior detail, loads of oil leaks, poor attention to mechanical reliability, barely running Weber 45 DCOE carbs, and an engine that coughed,shuddered and got real hot real fast. It really looked wild and got a great deal of attention though.

One of the first things

to address was the serious overheat problem. It was running real hot in England

and the South Florida heat definately bumped up the engine's initial C rise

rating. It turns out that the mystery Weber manifold had no provisions for a

thermostat. The AC condensor also throws off alot more heat so an additional

cooling fan located in the grill was added. After a little machine work to the

intake to fit a thermostat we take it for a drive on US 1 on some 96 degree

day in heavy traffic. Done deal.

The carbs are loading

up and fowling the spark plugs. When running Webers you really need to have

a good jet collection to tune these carbs. Some people collect stamps I collect

jets and emulsion tubes. We get the carbs set up with a good emulsion tube -

jet combo and switch to hotter plugs. We now have a great idle finally and Luc

decides to take it out and lay down some serious rubber. We found that we can

dump the clutch at 3500 RPM , stab the throttle and do massive burn outs! After

leaving a few 40 foot stretches of rubber we decide to retime the car and do

some further testing. I might add that these vintage Dunlop racing tires actually

hook up pretty good.

Further observations show that the car is breaking up at high revs. Oil is also leaking all over the front of the engine. When the English chaps mounted the crank sensor for the HPV-1 ignition they drilled mounting holes through the front of the oil pan, and stripped the threads. So we had a loose crank sensor with bolts that allowed oil to rain all over the front of the engine. Thierry Heli-coils the holes and we mount the sensor with the proper air gap and initial TDC timing and use some sealant on the bolts. At least we kill 2 problems with one operation.

|

The Electromotive HPV-1 system uses 3 coils to fire the plugs. Each coil fires 2 cylinders at a time. The module has 4 set points. The first is for base or initial timing. The second is for advance above 3000 RPM. The third is for a slight advance or retard above 8000 RPM and the 4th is a rev limiter. There is no distributer in the car. Having three coils instead of one allows for a longer coil saturation time between cylinder firings, thus a hotter spark. It really makes for a clean setup and makes setting or just playing with spark curves real fun. I settled with a 14 degree base and an 18 degree 3000 RPM set point yielding a total advance of 32 degrees. I like the rev limiter at 6200 RPM. |

Once the ignition was fixed

I decided to get rid of the "fluffy and amusing throttle response"

that Top Gear spoke of. I don't find it "fluffy or long" anymore.

I just reengineered the throttle linkage geometry and presto.... instant throttle

response. There were alot of minor hydraulic fitting problems resolved as well

as brake rotor and peg drive clearance issues. I still have an emergency brake

squeak that I can't seem to pinpoint. Considering there is absolutely no sound

insulation or carpet other than mats, the Low Drag is actually pretty quiet.

I had the exhaust headers coated by a company called Thermo Shield. They do

a similar coating like Jet Hot does.

Please turn to page 2 of this story.

| Main Site Entrance | Jaguar Entrance | Low Drag - Page 2 | Contact Us |